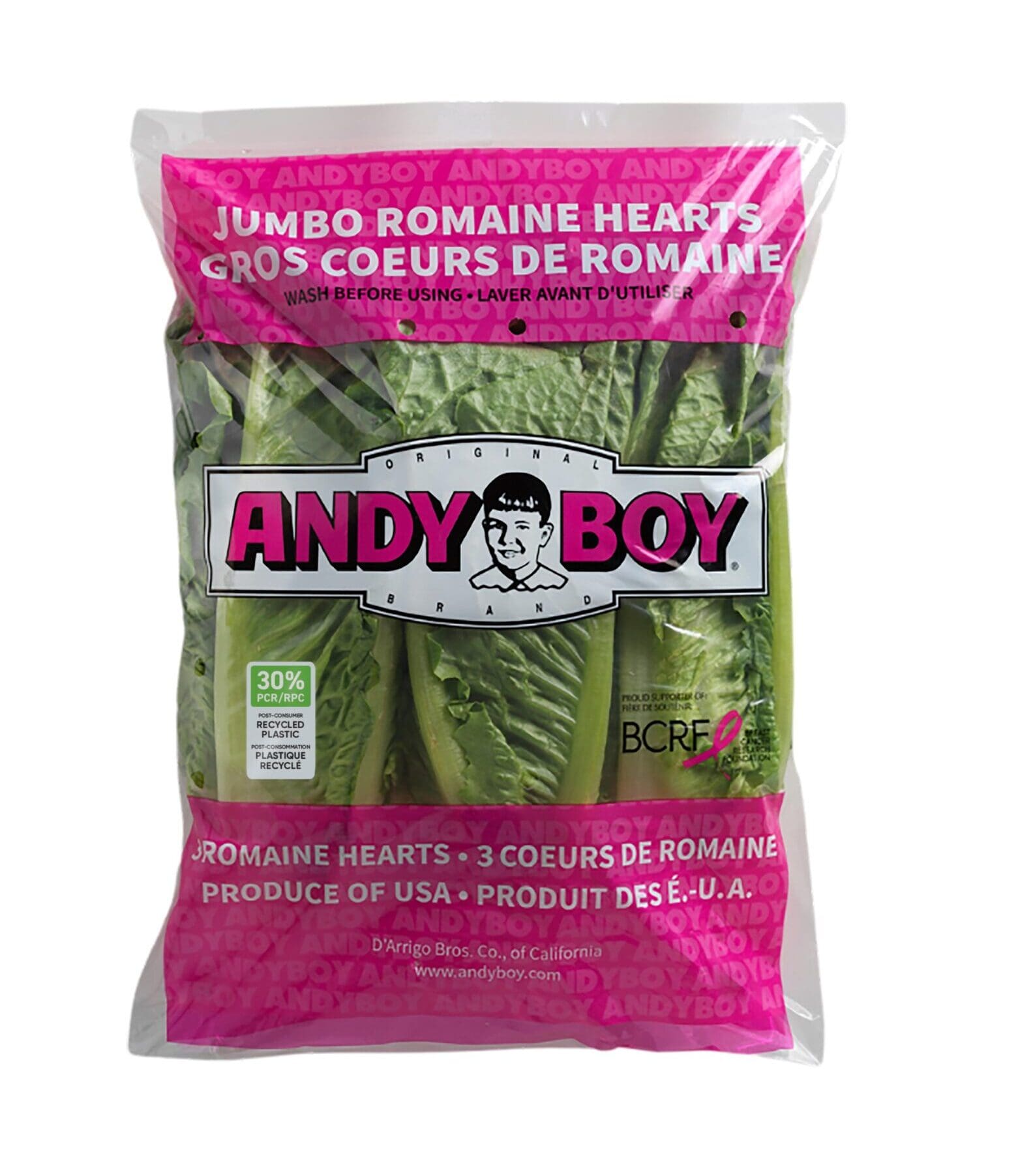

D’ARRIGO CALIFORNIA AND EMERALD PACKAGING DEBUT POST-CONSUMER RECYCLED (PCR) PLASTIC PACKAGING

Producing sustainable packaging is an environmental necessity today. Emerald Packaging, Inc. the leading flexible packaging company for produce in the U.S., has collaborated with D’Arrigo California, a leading grower, packer and shipper of fresh produce that ships under the Andy Boy label, to further develop a Post-Consumer Recycled (PCR) bag for its premiere romaine hearts products. The bag will be available in all grocers that carry Andy Boy romaine hearts across North America.

The two companies share a commitment to improving the environment in their respective industries. The new romaine hearts bag will be made up of 30 percent PCR plastic, helping D’Arrigo California and Emerald Packaging reduce the need for virgin plastic production, taking a step towards a more circular economy. The use of PCR reduces plastic pollution by diverting waste material from landfill, material that could also end up in the oceans.

D’Arrigo California has used 5 percent PCR in millions of their three count romaine heart bags since the beginning of the year, stepping up PCR content over the last several months. In December, D’Arrigo California will transition their two count romaine heart and three count romaine heart bags to 30 percent PCR, the current sweet spot for the resin in flexible packaging meant for grocery stores.

“Post-Consumer Recycled packaging is a big leap forward in sustainable plastics,” said Kevin Kelly, chief executive officer, Emerald Packaging, Inc. “It’s an exciting time in the industry as we take the critical steps towards achieving sustainability while doing it affordably. Emerald Packaging is dedicated to working closely with our customers such as D’Arrigo California to design packages that reduce the impact on the environment and allow them to meet their environmental goals.”

D’Arrigo California has a proven track record of integrating environmental initiatives into its daily operations, with a focus on making farming, as well as its packaging, more sustainable. Over the last few years, D’Arrigo California has cut the amount of plastic used in their romaine packaging by 25 percent and has also eliminated the zipper, which has reduced plastic by another 5 percent. Plastic reduction is a natural extension of D’Arrigo California’s overall sustainability efforts, which include commitments to recycling, solar power and water conservation.

“We’ve made substantial investments in solar power and recycling, and have implemented packaging solutions that substantially decrease our use of plastic and its environmental impact. The incorporation of post-consumer recycled (PCR) materials in our packaging exemplifies our unwavering commitment to sustainability,” said John D’Arrigo, President and CEO of D’Arrigo California. “We appreciate our enduring partnership with Emerald Packaging, a valued collaborator who shares our dedication to sustainability and innovation. They have played an instrumental role in advancing this cutting-edge technology.”

The PCR used in the new bags was produced by Circulus Holdings, a Houston-based company producing PCR from mechanically recycled low density polyethylene. Emerald has partnered with its Modesto, CA facility for over a year, working to manufacture packaging using Circulus’ PCR, which has a U.S. Food and Drug no objection letter, making it fit for food packaging.

Emerald Packaging has been reinventing produce packaging for 60 years and is the largest plastic packaging manufacturer for produce in the U.S. The company specializes in fresh produce and bagged salads for many of today’s leading food companies nationwide. For over two decades, Emerald Packaging has led the industry in addressing plastic waste, most recently helping shape legislation in California that addresses the need for a better recycling infrastructure. Emerald is one of the few

manufacturers to win a Green Business certification for its waste, water, and energy reduction efforts. It introduced the first compostable packaging in the produce industry 15 years ago and continues to test and experiment with new materials as they become available.

Emerald Packaging is also one of the few flexible packaging companies in the United States to become an Ellen MacArthur signatory. Under its MacArthur commitments, Emerald Packaging will help drive the adoption of post-consumer recycled resin (PCR) in food packaging and has agreed to make its packages reusable, recyclable or compostable in accordance with NPEGC principles, with specific targets to hit by 2025.